- ARTCAM 2015 GENERATE G CODE GENERATOR

- ARTCAM 2015 GENERATE G CODE SOFTWARE

- ARTCAM 2015 GENERATE G CODE CODE

How do I solve this? What Am I doing wrong?

ARTCAM 2015 GENERATE G CODE SOFTWARE

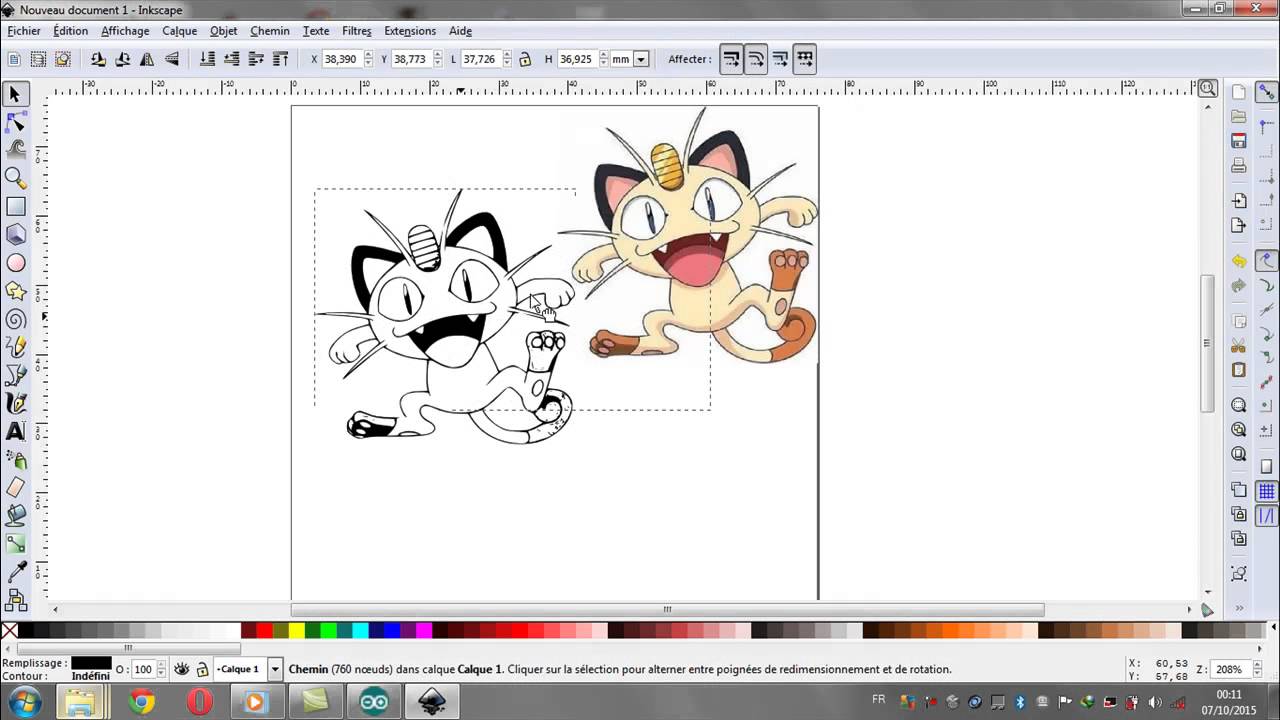

1 must be opened and re-saved in any version of ArtCAM software between 2013.SP R2.SP3 utilising a USB. This feature don't look to work very well.ġ - Create a Z level operation with a 10mm end mill Ģ - Click on the rest machining icon, it generates a vector ģ - Create a machine relief operation and choose a 4mm end mill for rough e 4mm ball nose for finishing.Īs you can see in the attached file, artcam makes the tool pass where theres no material and this is waste of time and money. Where customers are working in Carveco version 1.0.0 (Build: -2300-25c3bb5) through to 1.5 (Build: -1556-3e289e6), ArtCAM Project files (.3dp) originating from any version of ArtCAM software between. Now I starting to modeling something but have problems to understand how the rest machining works in ArtCAM. I'm trying to learn ArtCAM software, the approach it's very different of solidworks and that is keeping me very busy. I have a quotation for SolidCAM but it's almost impossible to spend all that money for while US$1,00=R$4,00 (R$ = Brazilian reais) so I started to look for a less expensive option.

ARTCAM 2015 GENERATE G CODE CODE

Well I design a 3 axis cnc to start to work with wood, my father has a lot of experience in this area, but not much experience with cnc machine so do I. free 3d cnc router artcam files download cnc router cut files cnc router cad files cnc router carving files cnc router cabinet files cnc router g code files. Well it's not a secret that things in Brazil are nothing going well and this made a lot of us, brazilians, to be creative and find another way to keep things going. I used to work with engineering for 20 years and with solidworks for 14 years.

OBJ file, convert it to G-Code with either RhinoCAM or ArtCAM, then import that into Mach3. I model complex shapes in Lightwave 3D, export it as an. Parameters on the Posting tab in the Machining Parameters dialog box Answer (1 of 3): For simple geometric shapes, profiles, pockets, etc., I just code it in Notepad, then load the text file into Mach3.The CNC Code (G-code) that is generated when a part is post processed in SOLIDWORKS CAM® or CAMWorks®.The CNC code that is generated can be optimized for your facility's machines and production methods.

ARTCAM 2015 GENERATE G CODE GENERATOR

The Universal Post Generator allows to you to customize post processors for both basic and complex code generation requirements and supports a variety of CNC machines and controls. The flexible, easy-to-use graphical interface of the Universal Post Generator or UPG is designed so users can quickly customize post processors to generate edit-free code for their machining environment.

Each post processor is designed to generate quality CNC code that meets the requirements of the machine control. SOLIDWORKS CAM® and CAMWorks® use a post processor to convert virtual information and toolpaths into machine tool specific CNC code (often called G-code) required for CNC machining.

0 kommentar(er)

0 kommentar(er)